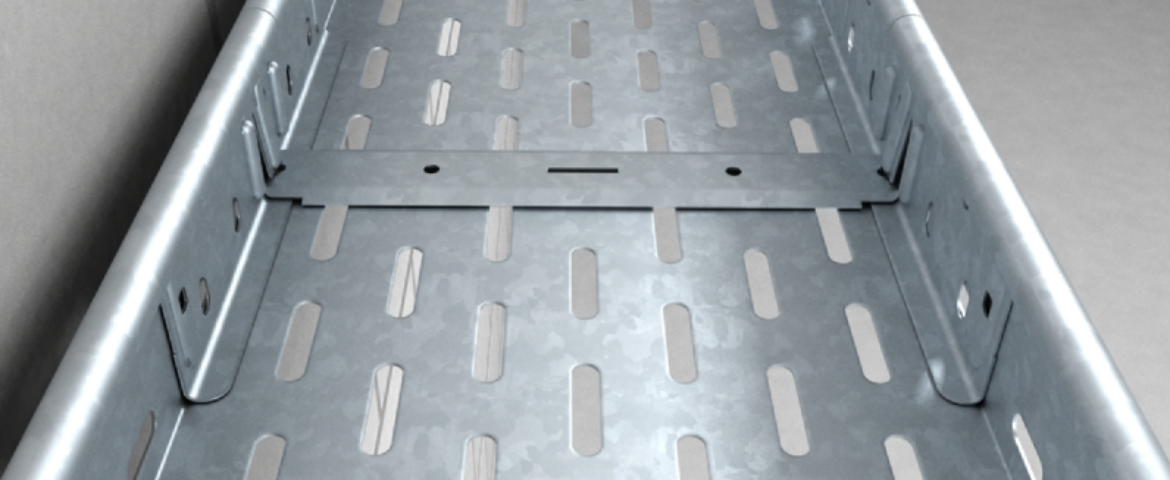

Cable Tray Joint Plate

A cable tray joint plate is an important part of any cable tray system. It connects two trays together and ensures a strong joint. These plates are used in industries, commercial buildings, and large projects. They help in keeping the trays aligned and safe. A reliable manufacturer always focuses on quality because joint plates carry heavy loads of wires and cables. The right installation also matters because poor fitting can cause loose connections or safety risks. In this article, you will learn about cable tray joint plate manufacturing, its types, installation steps, and benefits. This will help you choose the best option for your project and understand how to fix it properly.

What is a Cable Tray Joint Plate?

A cable tray joint plate is a flat metal piece used to join two cable trays. It comes with drilled holes for nuts and bolts. The main job of the plate is to hold trays in place and provide stability. Without a joint plate, trays may shift or bend. This can lead to damage to cables.

Importance of Using Joint Plates

Joint plates keep trays aligned.

They increase the strength of the cable tray system.

They make the installation secure and safe.

They allow trays to carry heavy wires without bending.

Materials Used in Manufacturing

Most joint plates are made from strong metals. Common materials include:

-

Mild Steel (MS) – Affordable and strong.

-

Stainless Steel (SS) – Rust-free and long-lasting.

-

Aluminum – Lightweight but durable.

Manufacturers also apply surface coatings like hot-dip galvanizing, powder coating, or zinc plating. These coatings protect the plate from rust and increase life span.

Types of Cable Tray Joint Plates

There are different types of joint plates used for cable trays. The choice depends on the design of the tray.

-

Straight Joint Plate – Connects trays in a straight line.

-

L-Type Joint Plate – Used for 90-degree turns.

-

T-Type Joint Plate – Connects three trays in a T-shape.

-

Cross Joint Plate – Used when four trays meet at one point.

Features of a Good Manufacturer

When choosing a manufacturer, you must check a few qualities:

-

Use of high-quality raw materials.

-

Proper cutting, drilling, and finishing.

-

Strong coatings for anti-rust protection.

-

Affordable pricing with bulk supply.

-

On-time delivery.

A reliable manufacturer also provides technical support for installation.

Installation of Cable Tray Joint Plates

Step 1: Preparation

-

Check the cable trays before installation.

-

Make sure both trays are of the same size.

-

Gather tools like nuts, bolts, spanners, and washers.

Step 2: Positioning the Plate

-

Place the joint plate at the connecting point.

-

Align the drilled holes with the tray holes.

Step 3: Fixing the Plate

-

Insert nuts and bolts into the holes.

-

Tighten them with a spanner.

-

Use washers for extra grip.

Step 4: Final Check

-

Make sure trays are straight.

-

Ensure there is no movement or gap.

-

Test by applying slight pressure.

Safety Tips During Installation

-

Always wear gloves and safety shoes.

-

Do not overtighten bolts as it may crack the coating.

-

Ensure the tray is supported properly before fixing the joint plate.

Benefits of Proper Installation

-

Long life of cable trays.

-

Protection of cables from damage.

-

Easy future maintenance.

-

Strong and safe structure.

Common Mistakes to Avoid

-

Using low-quality nuts and bolts.

-

Ignoring surface coating.

-

Installing without checking alignment.

-

Leaving gaps between trays.

Conclusion

Cable tray joint plates are small but very important. They connect trays and give strength to the system. Choosing a good manufacturer ensures you get durable and coated plates. Proper installation with nuts and bolts keeps trays safe and aligned. This avoids damage to cables and reduces future repair costs. With the right materials, correct type, and safe fitting, you can build a strong and long-lasting cable tray system.